The typical operating sequence for this valve is as follows. Directly connected or closely placed elbows are detrimental to pump opera-tion because of multiple and compounding reasons.

Temperature Creep In Hot Water Recirculation Caleffi

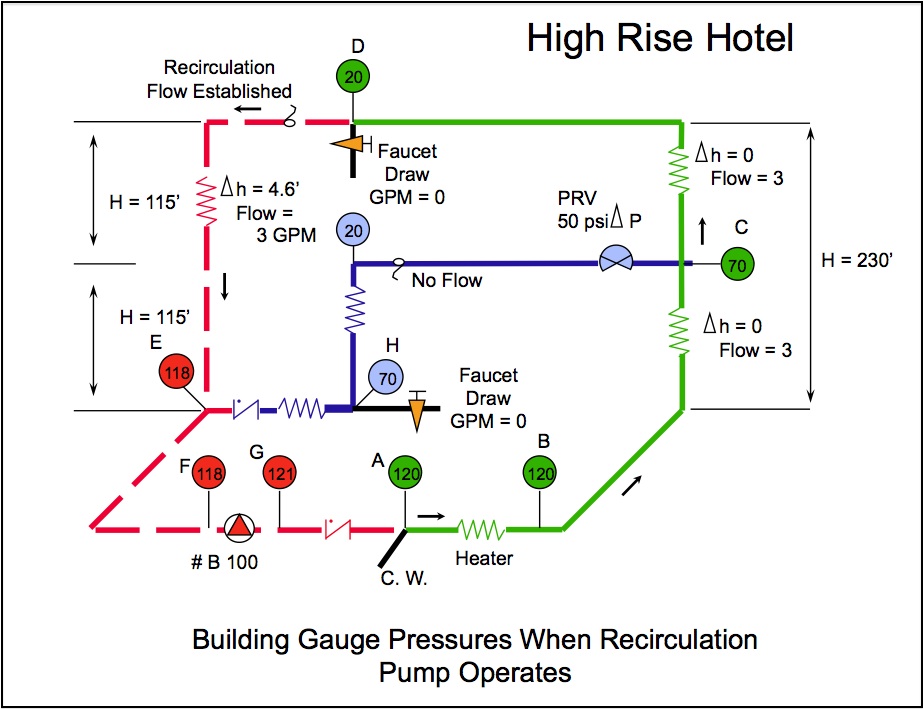

My suggestion is design the recirculation rate for 50 or 70.

. Points at which a slurry or suspended solids system connects with another system are called cross connections. Experienced engineers will tend to use their experience to bridge the gaps. Plug-and-pump design 115V Saves up to 12000 gallons of water per year.

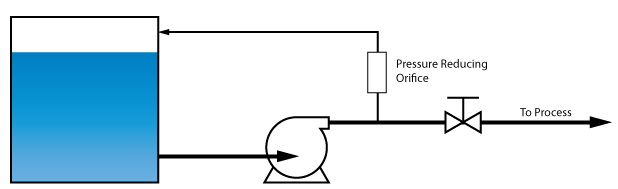

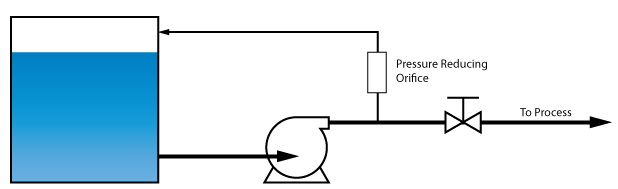

Once the feedwater valve reaches 10 to 25 of pump capacity the recirculation valve will go closed. A recirculating pump comfort system sends the unused hot water back to the water heater via the existing cold water line. 3 A PRL is required ONLY when there is risk of process cut-out or reduced flow usually in a hot oil or a cooling water circuit when the demand can reduce to zero or to a maximum high4 If there is no risk of deadheading the pump other than mistake of the process operator than there is no need for the PRL.

Unfortunately there is no specific rule of thumb. When you order your pump make sure that the motor is installed with spacer blocks so that the next largest motor frame can be installed. CircuitSolver design guide for flow pressure loss and recirculation pump sizing To determine pressure loss in the recirculation system we recommend the use of traditional pipe sizing and head loss practices.

If the pressure goes high it is an indicator of low flow all other factors being normalized. Their pump sizing software PUMP-FLO can help find the best pump for the application it can select the closest one to the BEP. Centrifugal pump recirculation line This long-awaited new edition is the complete reference for engineers and designers working on pump design and.

In many cases this will be the bathtub which requires approximately 10 gpm 06 Ls. Disregard for proper allowances can result in vortices cavitation and loss of prime. Point P3 The characteristic curve of the combined system bypass main pipe matches the pump performance curve.

For you and do all kinds of searches based on NPSHR efficiency size etc. In order to install it you will need. The problem normally arises at the design stage where pump is not yet available and hence minimum continuous stable flow is unknown.

This is commonly applied on PD pumps maybe not so common on centrifugal pumps but it would work and be more efficient than the steady parasitic load of a bypass line. Get the Job Done With the Most Dedicated Team Around. When the boiler feedpump is firststarted the recirculation valve will be opened and the feedwater valve will be slowly opened as the planned comes on line.

A slurry recirculation pump can be designed to keep this from happening. It is also vital that all hot water pipes are insulated. The steps to follow to select a centrifugal pump are.

Backflow means the undesirable reversal of flow of a liquid gas or suspended solid slurry into an unwanted area of the process. Determine the flow rate To size and select a centrifugal pump first determine the flow rate. If you are a home owner find out which of your uses for water is the biggest consumer.

This point is used to define the required H-Q rated point to select the pump. This utilizes a booster pump that forces the hot water to the fixture that is farthest away. You usually install the install the pump in the cabinet of the sink farthest from the water heater.

The pump functionality allows the homeowner to only run the hot water recirculation pump when there is demand saving thousands of gallons of water a year. All controls and software are built into the product by Grundfos making installation simple. This return system design ensures that there is always hot water in the trunk or main line but it is essential that the hot water recirculation lines are as close to all fixtures as possible.

Pump Minimum Recirculation Line. In case your water supply system is quite far away from the kitchen or shower a recirculating pump comfort system can help you get the system back into the task. An important aspect of pump hydraulic system design is the suction or inlet conditions.

Design guides published by ASPE. These pumps are equipped with a simple design and provide you access to an affordable hot water recirculation system.

What Is A Centrifugal Pump Minimum Flow Bypass Line

Domestic Hot Water Recirculation Part 8 Proper Application Of Pressure Reducing Valves

Process Engineering Properly Protect Centrifugal Pumps Chemical Processing

Domestic Hot Water Re Circulation System Design Pump Head Capacity Calculation Plumbing Design Youtube

Pump Minimum Flow Control Philosophy Query Industrial Professionals Cheresources Com Community

Hot Water Recirculation Systems Internachi

How To Identify Mitigate Low Flow Damage To Centrifugal Pumps Pumps Systems

0 comments

Post a Comment